If you’re looking to outfit your team with professional custom apparel, screen printed polos are likely on your shortlist. They’ve been a go-to choice for businesses, sports teams, and organisations for decades, and for good reason. But with other printing methods available, it’s worth understanding exactly what screen printing involves and whether it’s the right fit for your project.

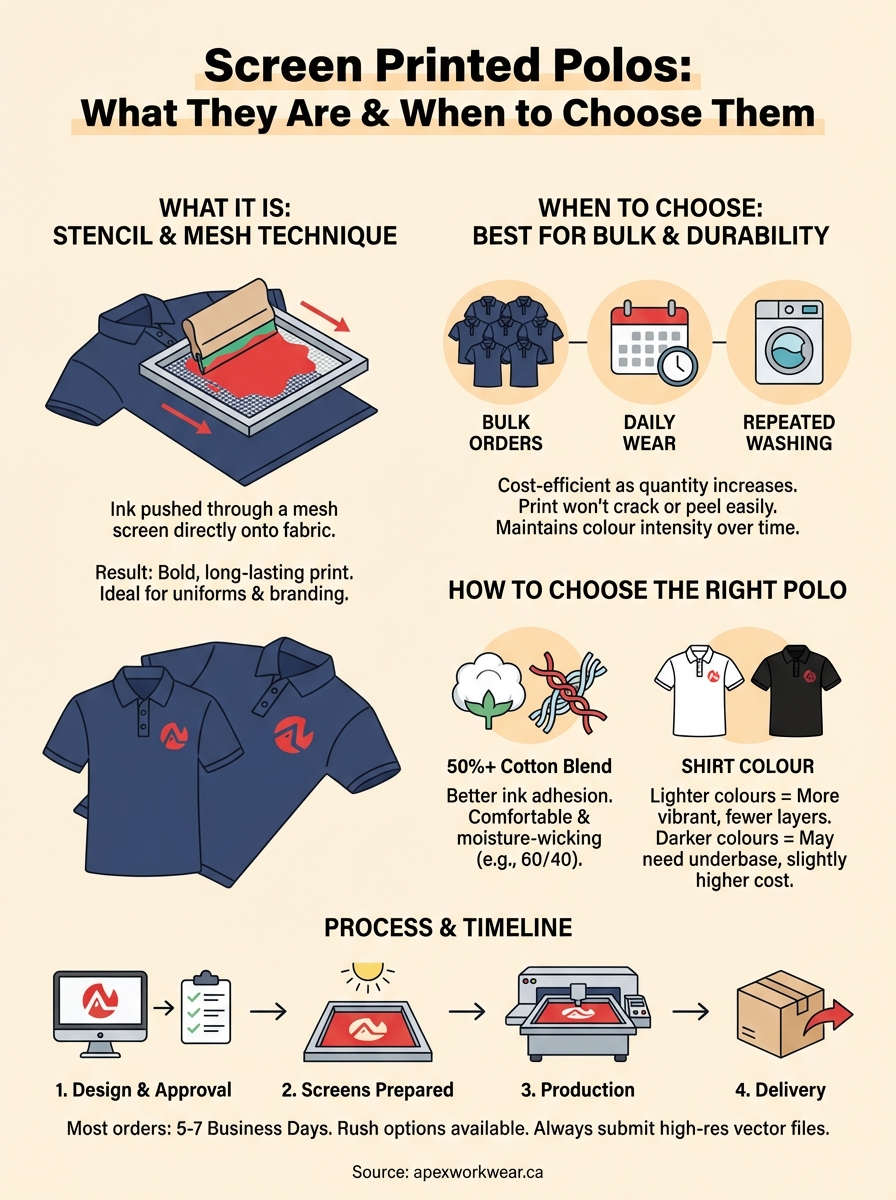

Screen printing uses a stencil-based technique to push ink directly through a mesh screen onto the fabric. The result is a bold, durable print that holds up well to washing and daily wear. That durability makes it particularly popular for uniforms, promotional events, and corporate branding where longevity matters.

This guide breaks down how screen printed polos are made, when they make the most sense, and how they compare to other options like embroidery or direct-to-garment printing. At Apex Workwear, we produce custom apparel right here in Canada, so whether you’re ordering ten polos or a few hundred, we’ll help you figure out which method delivers the best results for your brand.

Why screen printed polos are popular

Screen printed polos strike a balance between professional appearance and practical value that few other custom apparel options can match. You get a crisp, vibrant design that represents your brand well, without the premium price tag that often comes with embroidery. That combination makes them especially attractive when you’re outfitting an entire team or preparing for a trade show where you need dozens or hundreds of shirts.

Cost efficiency for larger orders

The economics of screen printing work in your favour as your order quantity increases. While there’s an upfront cost to create the screens (one for each colour in your design), that expense spreads across every shirt you print. Once the screens are made, adding more polos to your order becomes significantly cheaper per unit. If you’re ordering 50 shirts instead of 10, you’ll see a noticeable drop in the cost per piece.

This pricing structure makes screen printing the most budget-friendly option for bulk orders, particularly when you’re working with simple designs and limited colours.

Durability that outlasts the competition

Screen printed polos hold up remarkably well through repeated washing and daily wear. The ink bonds directly to the fabric fibres, creating a print that won’t crack, peel, or fade as quickly as some other methods. Your team can wear these shirts week after week without the design losing its punch. That durability matters when you’re investing in uniforms or branded apparel that needs to look professional for months or even years. The thicker ink deposit also means your colours stay bold and your logo stays readable, even after dozens of wash cycles.

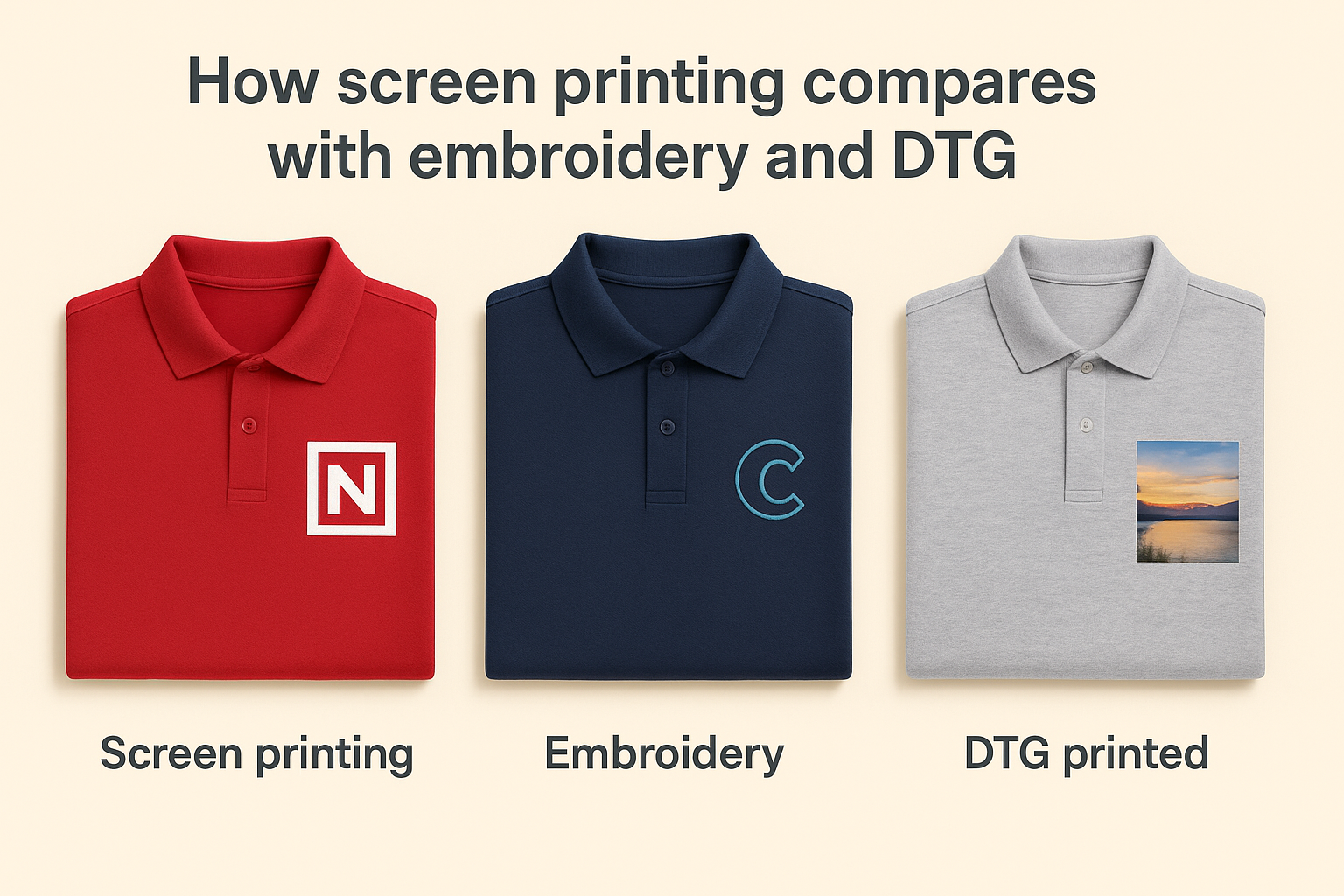

How screen printing compares with embroidery and DTG

When you’re deciding between printing methods for your custom polos, you’ll likely weigh screen printing against embroidery and direct-to-garment (DTG) printing. Each technique delivers different results, and understanding these differences helps you match the method to your specific needs. Screen printing excels with bold graphics and larger orders, while embroidery offers a premium textured finish, and DTG handles detailed photographic designs.

Screen printing vs embroidery

Embroidery creates a raised, textured design by stitching thread directly into the fabric, giving your logo a polished, professional appearance that’s particularly popular for executive wear. However, it costs significantly more per unit than screen printing, especially when your design includes multiple colours or fine details. Screen printed polos deliver vibrant, flat designs at a lower cost, making them ideal when you need quantity without sacrificing visual impact.

If you’re working with simple logos and ordering in bulk, screen printing typically offers better value than embroidery.

Screen printing vs DTG

DTG printing sprays ink directly onto the fabric like an inkjet printer, allowing for full-colour photographs and intricate gradients that screen printing can’t match. That flexibility comes with trade-offs: DTG works best for small orders (under 25 shirts) and produces prints that fade faster through washing. Screen printed polos maintain their colour intensity longer and become more economical as your order size grows beyond a few dozen units.

How to choose the right polo for screen printing

Not every polo shirt accepts screen printing ink equally well. The fabric blend and shirt colour you select directly affect how vibrant your design appears and how long it lasts through regular wear. Understanding these factors before you place your order saves you from disappointing results and wasted budget.

Fabric composition matters

Cotton-rich blends (typically 50% cotton or higher) provide the best surface for screen printing because the ink bonds more effectively with natural fibres. Pure polyester polos require special plastisol inks that sit on top of the fabric rather than soaking in, which can feel stiffer and crack more easily over time. Your ideal choice balances comfort with print durability, particularly if your team will wear these shirts daily in warm conditions.

Cotton-polyester blends around 60/40 deliver excellent print adhesion while maintaining moisture-wicking properties that keep wearers comfortable.

Colour considerations for optimal results

Darker shirt colours often require an underbase layer of white ink beneath your design to prevent the fabric colour from dulling your artwork. This extra layer adds production time and cost, though the results justify it when you need bright logos on navy or black polos. Lighter shirt colours allow your screen printed polos to display artwork more vividly with fewer ink layers, which translates to faster turnaround and lower pricing per unit.

What to expect from the printing process and timelines

Understanding the screen printing workflow helps you plan your order timeline and avoid last-minute rushes. The process moves through several distinct stages, from submitting your artwork to receiving your finished screen printed polos. Most orders take 5 to 7 business days from approval to shipment, though rush options can speed that up if you’re working against a tight deadline.

Design approval and preparation

You’ll start by submitting your artwork or logo to the printer, who reviews it for print compatibility and suggests any necessary adjustments. This design review typically happens within 24 hours, and you’ll receive a digital proof showing exactly how your design will appear on the shirt. Once you approve the proof, the printer creates the screens for your specific colours and prepares the production setup.

Approving your proof quickly keeps your order moving through production without delays.

Production and delivery timeframes

Production begins after you’ve signed off on the proof, with most standard orders shipping within 5 to 7 business days. Rush services can reduce that to 2 to 3 business days if you’re facing an urgent need, though they typically add 20 to 30 percent to your total cost. Shipping times vary based on your location, but orders within the Greater Toronto Area often qualify for free local delivery.

Common problems and how to avoid them

Even well-planned orders can hit snags if you overlook certain details during the setup phase. Most issues with screen printed polos stem from artwork preparation, colour expectations, or fabric choices that don’t match the printing method. You can sidestep these problems by understanding what causes them and making informed decisions before production starts.

Artwork resolution and file formats

Submitting low-resolution images leads to blurry, pixelated prints that damage your brand’s professional appearance. Your printer needs vector files (AI or EPS formats) or high-resolution raster images (at least 300 DPI) to produce sharp, clean results. Avoid pulling logos from your website or social media profiles, as these compressed images rarely meet printing standards.

Always request original design files from your graphic designer before placing your order.

Colour matching expectations

Screen colours on your monitor won’t perfectly match the printed ink colours on fabric, particularly when you’re working with Pantone-specific shades. Request a physical colour swatch or sample shirt if exact colour matching matters for your brand guidelines. Darker polo colours also absorb some of the ink’s vibrancy, so your bright red logo might appear slightly muted on a navy shirt without proper underbase layers.

Ready to order screen printed polos

You now understand how screen printing works, when it makes sense for your project, and how to avoid common pitfalls that waste time and money. Screen printed polos deliver durable, vibrant designs at prices that work for most budgets, particularly when you’re ordering in quantities of 25 units or more. The method handles bold logos and simple artwork exceptionally well, making it ideal for uniforms, promotional events, and team apparel that needs to withstand regular wear.

Your next step depends on your specific needs: fabric choice, colour count, and order quantity all influence your final cost and timeline. At Apex Workwear, we produce all our custom apparel right here in Canada, with most orders shipping within 5 to 7 business days and free local delivery available in the Greater Toronto Area. Get a free quote and we’ll review your design within 24 hours, suggesting improvements that help your brand look its best on professionally printed polos.