Whether you’re outfitting a team, launching merchandise, or branding your business, screen printed tshirts remain one of the most popular choices for custom apparel. The method has been around for decades, and for good reason, it delivers vibrant colours and exceptional durability that other printing techniques struggle to match, especially on larger orders.

But before you place an order, you probably have questions. How does the process actually work? What affects the price? And how do you know if screen printing is the right fit for your project? At Apex Workwear, we handle custom apparel orders daily across Canada, and we’ve seen firsthand how understanding the basics can help you make smarter decisions and get better results.

This guide breaks down everything you need to know about screen printed t-shirts, from the printing process itself to cost factors and quality considerations, so you can order with confidence.

What screen printed tshirts are

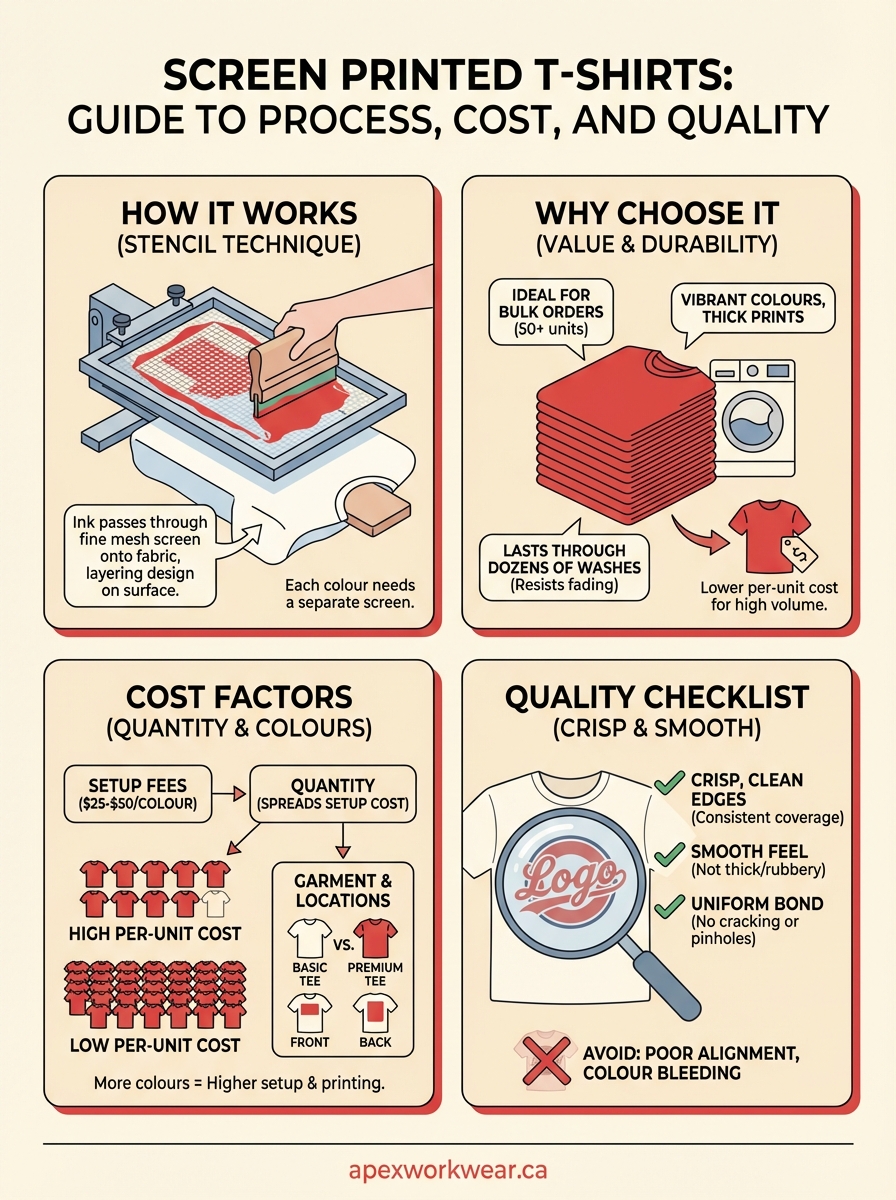

Screen printed tshirts use a stencil-based technique where ink passes through a fine mesh screen onto fabric. The method creates bold, opaque designs by layering ink directly on the shirt’s surface, rather than embedding it into the fibres like some digital methods. Each colour in your design requires its own separate screen, which is why the process works best for simpler graphics with fewer colours.

The basic technique

The process starts with creating a stencil (called a screen) for each colour in your design. Workers coat a mesh screen with a light-sensitive emulsion, then expose it to UV light with your design template on top. The areas exposed to light harden, while the covered areas wash away, leaving a precise stencil through which ink can pass. During printing, workers place the screen over your t-shirt, apply ink on top, and use a squeegee to push the ink through the open areas of the mesh.

Screen printing excels when you need durable, vibrant prints that can withstand repeated washing without fading.

What makes screen printed tshirts different

Unlike direct-to-garment (DTG) printing, which sprays ink similar to an inkjet printer, screen printing sits on top of the fabric. This creates thicker, more durable prints that hold their colour intensity through dozens of wash cycles. The technique also handles high-volume orders more efficiently because once you create the screens, you can produce hundreds or thousands of identical shirts quickly. However, each additional colour adds time and cost to setup, which is why screen printed tshirts work best for designs with one to four colours rather than full-colour photographs or complex gradients.

Why businesses choose screen printed tees

Businesses gravitate towards screen printed tshirts because the method delivers unmatched value at scale. When you order 50, 100, or 500 shirts, the per-unit cost drops significantly because the expensive part (creating the screens) happens once. After setup, printing additional shirts takes minimal time and materials, which makes screen printing the most economical choice for team uniforms, event merchandise, or promotional giveaways.

Cost efficiency for bulk orders

The economics work in your favour when you order in volume. Setup costs typically range from $25 to $50 per colour, but this fixed expense spreads across your entire order. If you order 100 shirts with a two-colour design, that $100 in setup fees adds just $1 per shirt, while the actual printing might cost $3-5 per shirt depending on the garment. Compare this to DTG printing, where each shirt costs roughly the same regardless of quantity, and you’ll see why screen printing dominates bulk orders.

Screen printing becomes more cost-effective as your order size increases, making it ideal for businesses that need dozens or hundreds of identical shirts.

Durability that lasts

Your screen printed designs withstand commercial washing and daily wear better than most alternatives. The thick ink layer creates a resilient bond with the fabric that resists cracking, fading, and peeling through dozens of wash cycles. For businesses that need uniforms or workwear to maintain a professional appearance over months or years, this longevity matters.

How screen printing works step by step

Understanding the production process helps you set realistic timelines and appreciate what goes into quality screen printed tshirts. The method involves multiple stages that require precision and craftsmanship, from preparing your artwork to curing the final print. Each step builds on the previous one, and rushing any part can compromise your results.

Design preparation and screen creation

Your printer first converts your artwork into separate colour layers, creating a film positive for each hue in your design. Workers coat fine mesh screens with light-sensitive emulsion, then expose each screen to UV light with the corresponding film on top. The light hardens the exposed emulsion while the covered areas remain soft and wash away, leaving precise stencils that match your design exactly.

The printing process

Printers secure your t-shirt on a flat surface called a platen, then position the first colour screen above it. They apply ink on top of the screen and use a rubber squeegee to push the ink through the mesh openings. The shirt moves to the next station for each additional colour, and workers carefully align each screen to ensure your design layers properly.

Proper alignment between colour layers determines whether your final print looks professional or misregistered.

Curing and finishing

After printing all colours, your shirt passes through a heat tunnel or dryer that reaches temperatures around 160-180°C. This heat permanently bonds the ink to the fabric, creating the durable finish that makes screen printed tshirts last through countless washes.

What screen printed tshirts cost in Canada

Pricing for screen printed tshirts depends on three main factors: the number of colours in your design, the quantity you order, and the quality of the blank garments you choose. Canadian printers typically charge setup fees for creating screens plus a per-shirt printing cost that decreases as your order size grows. You’ll find the sweet spot for affordability usually starts around 50 units, where the economics of screen printing begin to outweigh alternatives like DTG or heat transfer vinyl.

Setup and per-unit costs

Screen creation runs $25 to $50 per colour, which represents your upfront investment before any shirts get printed. After setup, expect to pay $3 to $8 per shirt depending on garment quality and print complexity. A basic 100-shirt order with a two-colour design on standard cotton tees might cost around $600 total, breaking down to roughly $6 per shirt including both setup and printing.

Your per-unit price drops significantly when you order larger quantities because setup costs spread across more shirts.

Factors that affect your price

Garment selection impacts your budget substantially. Premium brands like Gildan Heavy Cotton or Bella+Canvas cost more than basic economy tees, typically adding $2 to $5 per shirt. Additional colours beyond the first increase both setup and printing costs, while printing locations (front, back, sleeves) multiply expenses further. Rush orders also carry premium fees, usually 20-30% above standard turnaround pricing.

How to judge quality and avoid issues

Quality screen printed tshirts show crisp, clean edges where colours meet and maintain consistent ink coverage across your entire design. Before you approve any order, you need to inspect sample prints carefully and understand what separates professional work from rushed jobs. Canadian printers should provide digital proofs before production starts, giving you the chance to catch alignment issues, colour mismatches, or design problems that cost money to fix later.

Check prints before accepting delivery

Examine your shirts in natural daylight rather than under artificial lighting, which can mask colour inconsistencies or defects. Run your fingers across the printed areas to feel for rough textures or ink buildup that suggests improper curing. The print should feel smooth and slightly raised but not thick or rubbery. Check that all colours align properly without gaps or overlapping where they shouldn’t, and verify that the design sits centred on the garment exactly where you specified.

Catching quality issues before you accept delivery saves you the headache of returns and rush reorders.

Watch for common defects

Poor screen printed tshirts often show pinholes (tiny dots where ink didn’t transfer), colour bleeding where adjacent hues mix, or cracking that appears even before washing. Ink should bond uniformly to the fabric without creating stiff, plasticky patches that restrict the shirt’s natural drape.

Next steps for your custom tees

You now understand how screen printed tshirts work, what they cost, and how to spot quality issues before accepting delivery. Armed with this knowledge, you can make informed decisions about your order quantity, colour choices, and garment selection that match both your budget and timeline.

Getting started requires clear artwork in a vector format (AI, EPS, or high-resolution PDF) and a sense of your order quantity. Most Canadian printers need 5-7 business days for standard orders, though rush services exist when deadlines loom. Reach out to printers early to discuss your specific needs, particularly if you have questions about colour matching, fabric choices, or design adjustments that could save money without compromising your vision.

Ready to bring your custom apparel to life? Apex Workwear handles screen printed orders for businesses across Canada with honest pricing, fast turnaround, and expert guidance from design to delivery. Contact us for a free quote within 24 hours.