Booklet printing in Canada means ordering custom printed and bound multi-page documents from Canadian print shops. You get physical booklets for catalogues, manuals, programmes, magazines, or marketing materials. The process involves choosing your format (page count, paper, size), selecting a binding method (saddle stitch or perfect bound), uploading your design files, and receiving finished booklets delivered to your door. Most Canadian printers handle everything from short runs for events to bulk orders for ongoing distribution.

This guide breaks down what you need to know before ordering. You’ll learn how to pick the right format and binding for your project, what affects pricing, and how to prepare files that print cleanly the first time. We’ll cover typical costs across Canada, compare the major binding styles, and show you where small businesses often save money or run into problems. By the end, you’ll know exactly what to ask for and what to expect when you place your order.

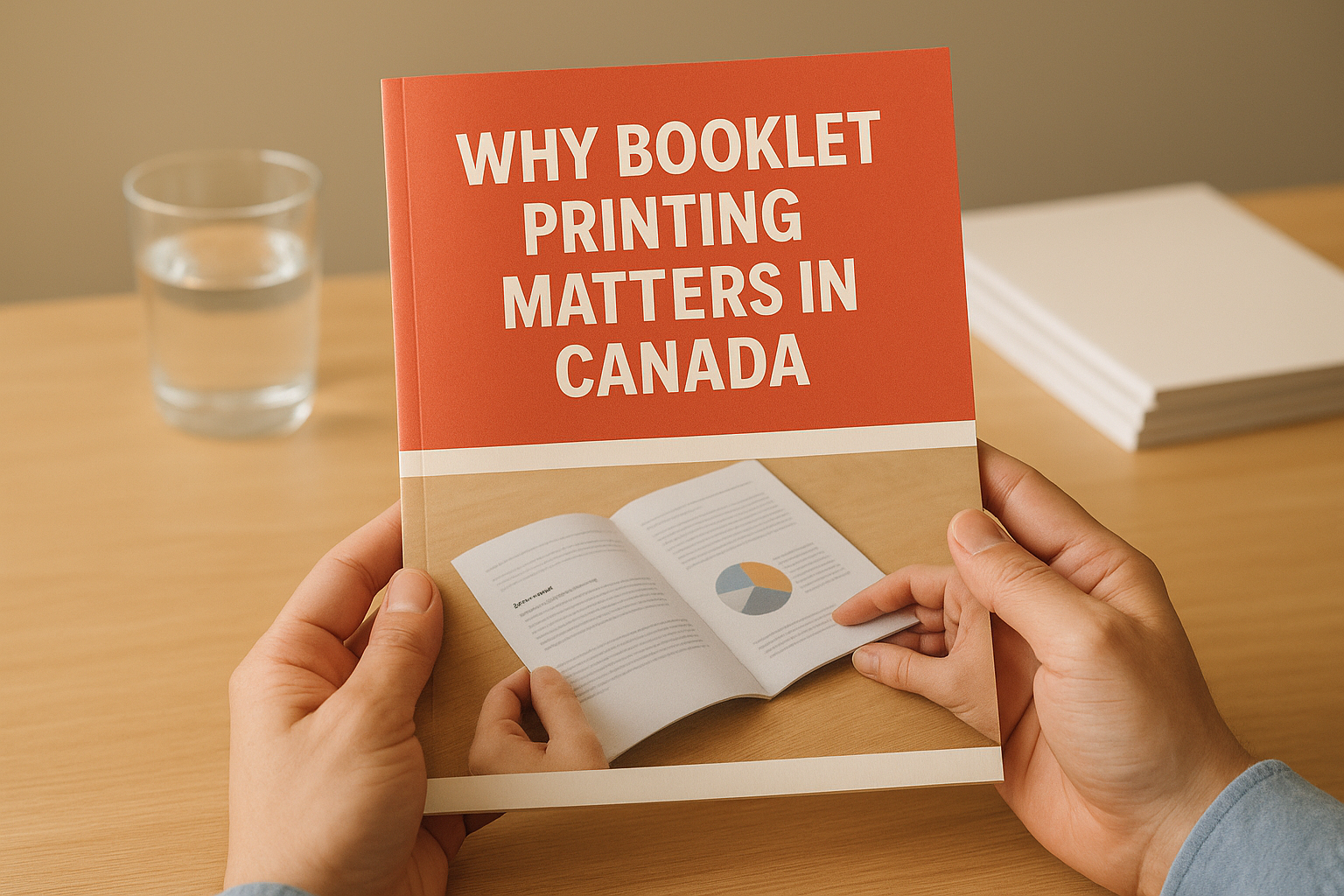

Why booklet printing matters in Canada

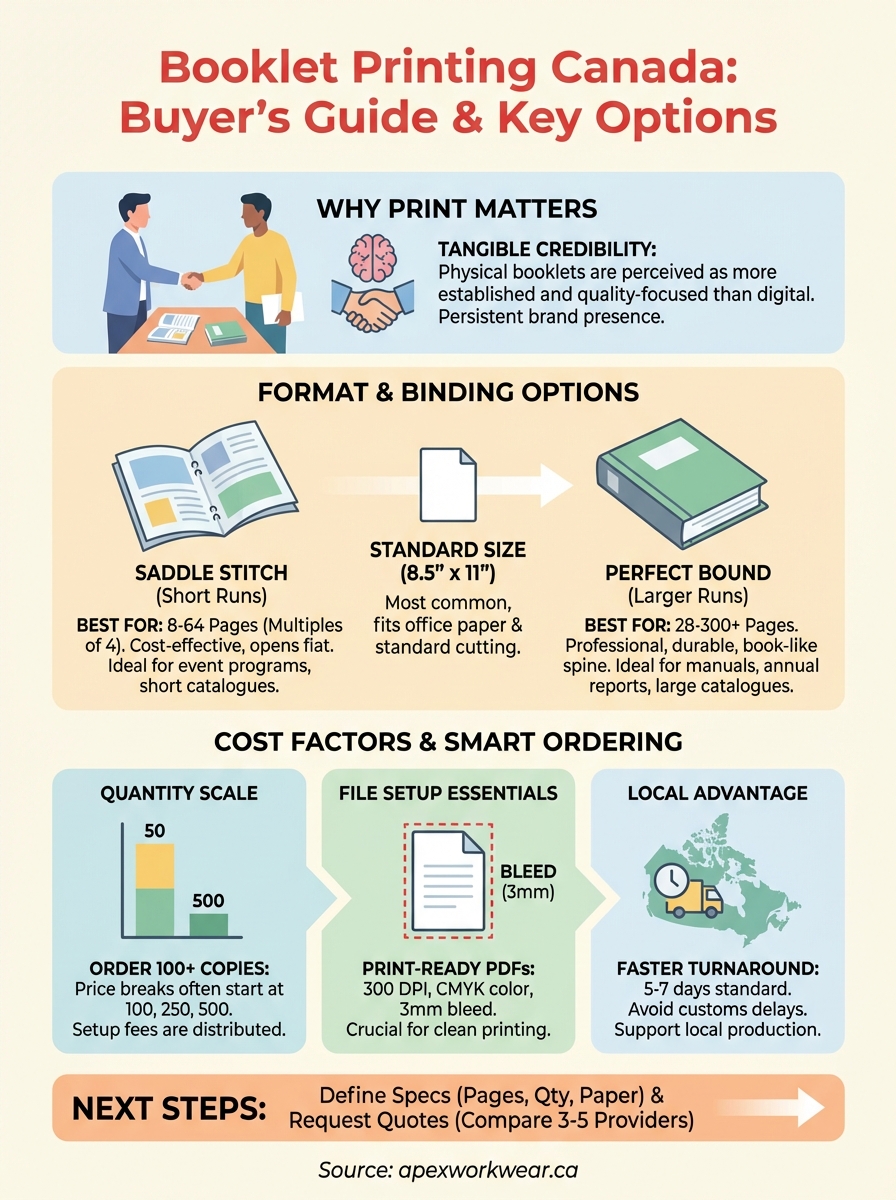

Physical booklets still carry more credibility than digital alternatives in many Canadian business contexts. When you hand a client a printed catalogue or training manual, they perceive your organisation as more established and committed to quality. Trade shows, conferences, and sales meetings across Canada rely heavily on tangible materials that prospects can take home, refer back to, and share with decision-makers. Your competitors who skip printed materials often lose opportunities simply because their brand isn’t physically present after the initial conversation.

Cost-effective marketing at scale

Booklet printing canada delivers some of the lowest per-unit costs for distributing detailed information. Once you move past 100 copies, the economics shift dramatically in favour of print. A 20-page saddle-stitched booklet might cost $8 each for 50 copies but drop to under $2 per booklet at 500 copies. You can distribute these at events, mail them to prospects, or leave them in waiting rooms without worrying about screen time, battery life, or internet connectivity. The physical format ensures your message stays in front of people for weeks or months.

Printed booklets provide a tangible brand presence that persists long after digital impressions fade.

Local production advantages

Canadian print shops offer faster turnaround times and simpler logistics than overseas alternatives. You avoid customs delays, currency fluctuations, and the carbon footprint of international shipping. Most domestic printers deliver within five to seven business days from file approval, with rush options for urgent projects. When quality issues arise, you can speak directly with production staff in your time zone and arrange reprints quickly. Local suppliers also understand Canadian paper standards, postal regulations, and regional preferences that affect how your finished booklets perform in the field.

How to choose and order booklet printing in Canada

Start by defining exactly what you need before you contact any printer. You’ll waste time and money if you request quotes without knowing your page count, quantity, paper weight, and delivery deadline. Canadian printers need these basic specifications to calculate accurate pricing, and missing details lead to back-and-forth emails that delay your project. Write down your requirements in a simple list: how many pages (must be divisible by 4 for saddle stitch), how many copies, what size (8.5" x 11" is standard), and whether you need glossy or matte paper. These decisions affect both cost and production time significantly.

Define your project specifications first

Your page count determines which binding methods work for your booklet. Saddle stitch binding (staples through the fold) handles 8 to 64 pages efficiently, whilst perfect binding (glued square spine) suits 28 to 300 pages. If you’re printing a product catalogue with 24 pages, saddle stitch costs less and ships faster. Training manuals with 80 pages require perfect binding for durability. Paper weight also matters because lighter stock (60-70 lb) works for short-term materials like event programmes, whilst heavier stock (80-100 lb) feels more premium and lasts longer in catalogues that customers keep for months.

Quantity affects your unit price more than any other factor. Order at least 100 copies to access reasonable per-unit costs, because setup fees for plates and press time don’t scale down proportionally for tiny runs. Most Canadian printers offer price breaks at 100, 250, 500, and 1,000 copies, with the steepest discounts kicking in after 250 units.

Compare Canadian printer options

Search for "booklet printing canada" and shortlist three to five providers that display transparent pricing and turnaround times on their websites. Request quotes from each with your exact specifications, and ask specifically about file requirements, proof options, and shipping costs to your location. Some printers include free shipping within major metros like Toronto, Vancouver, or Montreal, whilst others charge $20 to $50 for courier delivery. Rush fees can add 25% to 50% to your base cost if you need booklets within 48 to 72 hours instead of the standard five to seven business days.

Compare at least three quotes with identical specifications to identify true value beyond the headline price.

Check customer reviews for quality issues, missed deadlines, or poor communication before placing large orders. Order a small test run (50 to 100 copies) from a new printer before committing to 500 or 1,000 units, especially if your booklets require colour accuracy or precise alignment across the fold.

Submit files and review proofs

Upload your files as print-ready PDFs with embedded fonts and high-resolution images (300 DPI minimum). Most Canadian printers reject files below this standard or charge extra for fixing them. Include 3mm bleed on all edges if your design has colour or images extending to the page edge, because cutting tolerances vary slightly between press runs. Double-check that your page order flows correctly when printed double-sided, with page 1 on the right side of the first spread.

Request a digital proof before approving production, and review it carefully on a calibrated monitor. Look for colour shifts, text cut-offs near margins, and proper alignment across the centre fold. Physical proofs cost $25 to $75 extra but prevent expensive mistakes on large runs where reprinting 500 booklets could cost thousands. Approve your proof within 24 hours to keep your production slot, because delays push your job back in the print queue.

Key booklet formats and binding options

Your binding choice fundamentally changes how your booklet functions and how much it costs to produce. Canadian printers offer two primary binding methods that suit different page counts and use cases, and understanding their technical limitations helps you avoid ordering something that won’t work for your content. The format you select also affects how readers interact with your material, whether they can lay it flat on a desk, and how long the booklet survives regular handling. Most booklet printing canada projects fall into saddle stitch or perfect binding categories based on page count and budget constraints.

Saddle stitch binding

Saddle stitch uses two or three staples through the spine fold to hold pages together, creating a simple, cost-effective booklet that opens relatively flat. This method works best for 8 to 64 pages (always in multiples of 4), and most Canadian printers recommend staying under 48 pages for professional results. Beyond 48 pages, the booklet’s inner pages start creeping outward from the spine, requiring extra trimming that can cut into your content margins. You’ll see saddle stitch used for event programmes, product catalogues, company newsletters, and promotional brochures where the material has a short to medium lifespan.

The main advantage is speed and affordability, with saddle stitched booklets typically costing 30% to 50% less than perfect bound alternatives at the same page count. Setup takes less time because printers don’t need to mill the spine or apply adhesive, which means faster turnaround when you’re working against tight deadlines. The format also allows pages to lie nearly flat when opened, making it easier for readers to scan content or fill out forms printed inside.

Perfect binding

Perfect binding creates a square, glued spine that gives booklets a more polished, book-like appearance. Canadian printers use this method for 28 to 300 pages, applying hot-melt adhesive to hold the pages together and wrapping them with a cover that extends around the spine. You’ll recognise this binding from paperback books, training manuals, annual reports, and thick product catalogues where durability and professional presentation matter more than lowest cost. The square spine also allows you to print text and graphics along it, making your booklets easier to identify when shelved or stacked.

This binding method costs more because of additional production steps and materials. Printers must mill (roughen) the spine edge, apply adhesive evenly, attach the cover precisely, and trim all four edges for clean results. Expect to pay 40% to 60% more than saddle stitch for similar page counts in the 28 to 48 page range. Perfect bound booklets also don’t open completely flat, which can frustrate readers trying to photocopy pages or work from the material whilst taking notes.

Perfect binding becomes cost-competitive with saddle stitch once your page count exceeds 48 pages.

Standard size options

Most Canadian printers stock 8.5" x 11" (letter size) as their default booklet format because it matches standard office paper and fits easily into briefcases or filing systems. You’ll pay less for this size since printers can run multiple copies per press sheet and don’t need to adjust their cutting equipment. 5.5" x 8.5" (half letter) works well for handheld booklets like pocket guides, menus, or mini-catalogues where portability matters more than expansive layouts. Custom sizes like 6" x 9" or 8" x 10" cost 15% to 25% more due to paper waste and additional setup time, but they help your booklets stand out when competing for attention at trade shows or in direct mail campaigns.

Design and file setup tips for clean results

Your file preparation determines whether your booklets print correctly the first time or require expensive reprints after production. Canadian printers reject or charge extra for files with missing bleeds, low-resolution images, or incorrect colour modes, so getting these technical details right saves you both time and money. Most booklet printing canada problems trace back to design files that looked perfect on screen but failed when sent to commercial presses. You need to understand three critical areas: bleeds and margins, export settings, and thorough proofing before you upload anything to a printer.

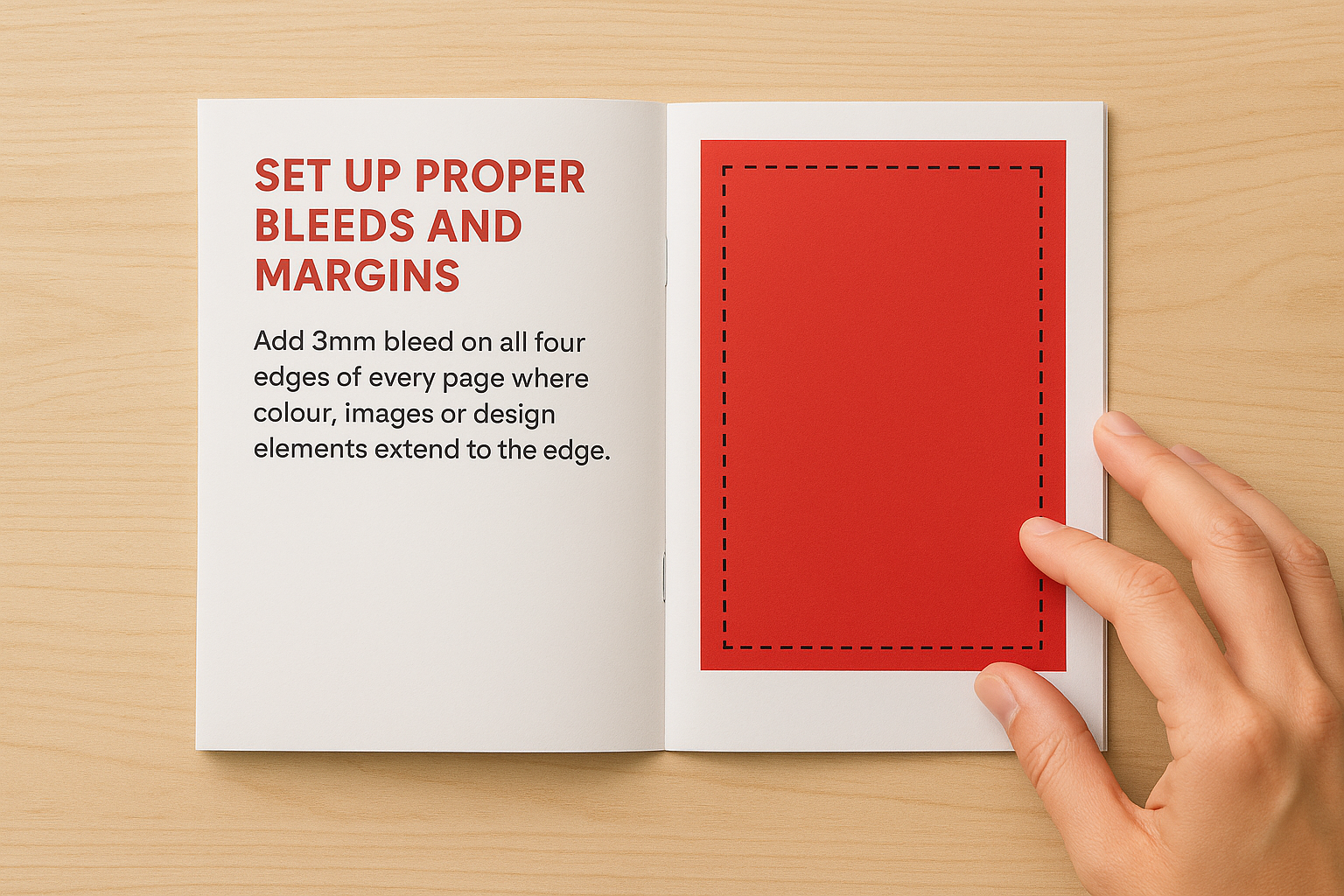

Set up proper bleeds and margins

Add 3mm bleed on all four edges of every page where colour, images, or design elements extend to the edge. Bleeds compensate for slight cutting variations during trimming, preventing white slivers along your finished edges. You also need to keep all text and critical content at least 6mm inside from all edges (the safe zone), because anything closer risks getting trimmed off during production. Pages that ignore these margins often end up with headlines or phone numbers partially cut away, making your booklets look unprofessional and potentially unusable.

Design files without proper bleeds and margins account for most booklet printing delays and quality issues.

Export files correctly

Save your final booklet as a high-resolution PDF with all fonts embedded and images at 300 DPI minimum. Use CMYK colour mode rather than RGB, because RGB colours won’t reproduce accurately on commercial presses and can shift dramatically from what you see on your monitor. Export with spreads disabled so each page becomes a separate PDF page, allowing printers to impose them correctly for their equipment. Files saved at 72 or 150 DPI produce blurry text and pixelated images that become obvious in print, even if they looked acceptable on screen.

Proof your layout carefully

Check that your page numbers run sequentially and that facing pages align properly across the centre spread. Review every page for typos, incorrect contact information, or outdated pricing before sending files to production. Print a desktop test copy on your office printer to catch layout problems that aren’t obvious on screen, particularly issues with text flowing across the gutter (centre fold). Small mistakes multiply across hundreds of copies, turning minor oversights into significant financial losses when you need to reprint entire runs.

Typical booklet printing costs in Canada

Understanding booklet printing canada costs helps you budget accurately and avoid surprises when quotes arrive. Pricing varies significantly based on quantity, page count, paper quality, and binding method, with most Canadian printers charging between $1.50 and $8.00 per booklet depending on these factors. Small runs under 100 copies cost substantially more per unit because setup fees (plate preparation, press setup, colour calibration) get divided across fewer booklets. You’ll achieve the best value by ordering at least 250 to 500 copies where economies of scale reduce your per-unit cost by 50% to 70% compared to ordering just 50 or 100 copies.

Base pricing by quantity and format

A standard 24-page saddle stitched booklet (8.5" x 11", 80 lb text paper, full colour) typically costs $6.50 to $8.00 each for 50 copies, dropping to $3.00 to $4.00 at 100 copies, and reaching $1.50 to $2.50 at 500 copies from most Canadian printers. Perfect bound booklets with 48 pages and a heavier cover start around $8.50 to $10.00 each for 50 copies, falling to $4.50 to $6.00 at 100 copies, and settling near $3.00 to $4.50 at 500 copies. Black and white printing cuts costs by 40% to 60% compared to full colour, making it economical for internal training materials or technical manuals where colour isn’t essential.

Order at least 250 copies to access the most favourable pricing tiers where per-unit costs drop dramatically.

Larger page counts push costs higher linearly. A 64-page saddle stitched booklet costs roughly 35% to 45% more than a 24-page version at the same quantity, whilst 100-page perfect bound booklets run approximately double the price of 48-page equivalents. Premium paper stocks (100 lb gloss text or 14pt cover) add $0.30 to $0.80 per booklet depending on your page count and quantity.

Additional cost factors

Rush production adds 25% to 50% to your base price when you need booklets within 48 to 72 hours instead of standard five to seven business day turnaround. Shipping costs vary from free (for orders over $100 to $200 within major metros) to $25 to $75 for courier delivery across provinces. Custom sizes outside standard dimensions incur 15% to 25% surcharges due to paper waste and additional cutting setup. Special finishes like spot UV coating, embossing, or foil stamping can add $0.50 to $3.00 per booklet depending on coverage area and complexity. Budget an extra $50 to $100 for physical proofs if colour accuracy or precise alignment matters critically for your project.

Next steps

You now understand how booklet printing canada works, what formats suit different projects, and how pricing scales with quantity and specifications. Start by finalising your page count, binding method, and paper choices based on how your audience will use the booklets. Gather your design files and verify they meet the technical requirements for bleeds, margins, and resolution before requesting quotes from Canadian printers.

Request quotes from three to five providers with identical specifications to compare pricing, turnaround times, and service quality. Order a small test run if you’re working with a new printer or need to verify colour accuracy for brand-critical materials. Get a quote for your booklet printing project from a Canadian printer that handles both small and large runs with transparent pricing and fast turnaround. Place your order with enough lead time for standard production and shipping to avoid rush fees.