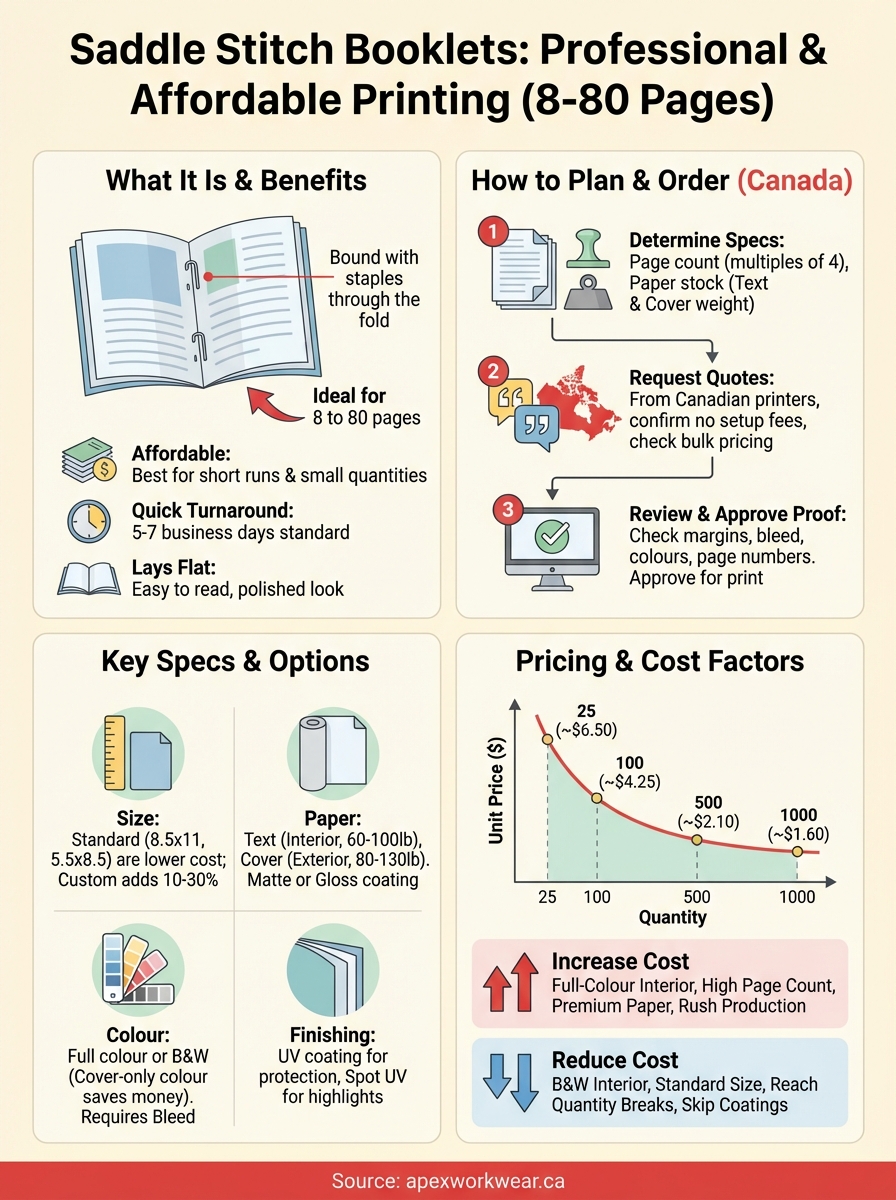

Saddle stitch booklets are bound with metal staples driven through the fold of the spine. You see them everywhere: product catalogues, event programs, corporate brochures, training manuals, restaurant menus. The binding method gets its name from the saddle shaped support that holds pages in place during stitching. These booklets work best for projects with 8 to 80 pages and offer one of the most affordable ways to create professional printed materials.

This guide breaks down everything you need to make smart decisions about saddle stitch booklet printing in Canada. You’ll learn when this binding method makes sense for your project, how to choose the right specs for your needs, what pricing looks like at different quantities, and how saddle stitching compares to other binding options. Whether you’re ordering 25 booklets for a local event or 5,000 catalogues for your business, you’ll know exactly what to expect from the process and what to ask for when you request a quote.

Why saddle stitch booklets are a smart choice

Saddle stitch booklets give you the best balance of professional appearance and affordable pricing for short-run print projects. The binding method costs less than perfect binding or coil binding because it requires fewer materials and simpler equipment. You pay only for paper stock and metal staples, which keeps your per-unit cost low even when you order small quantities. Production moves fast since printers can saddle stitch hundreds of booklets per hour, and most Canadian print shops stock the materials needed to complete your order within five to seven business days.

Budget-friendly for small quantities

Your project stays affordable whether you order 25 booklets or 5,000 copies. The simple binding process means printers don’t charge setup fees for specialty equipment or materials. Small businesses benefit most from this pricing structure because you can test different versions of your marketing materials without committing to large print runs. You’ll find saddle stitch binding costs roughly 30 to 50 percent less than perfect binding for orders under 500 units.

"The straightforward production process translates directly to lower costs for your business without sacrificing quality."

Quick turnaround and professional results

Printers complete saddle stitch projects faster than any other booklet binding method. You receive clean, flat spines that lay open easily for readers, making your content more accessible than spiral-bound alternatives. The finished product looks polished enough for client presentations, sales materials, and corporate events. Your booklets hold up well with normal handling, and the binding stays secure through multiple readings as long as you keep page counts within the recommended range.

How to plan and order saddle stitch booklets in Canada

Planning your saddle stitch booklet project starts with clear decisions about page count, paper stock, and quantity. You need to determine these basics before contacting Canadian printers because they affect both pricing and production timelines. Start by counting your total pages, remembering that saddle stitch booklets require page counts in multiples of four (8, 12, 16, 20, and so on up to 80 pages). Your cover counts as four pages, and you add inner pages from there. Most Canadian print shops handle everything from simple 8-page brochures to comprehensive 80-page catalogues, giving you flexibility for different project types.

Determine your page count and paper requirements

Calculate your total page count by laying out your content in a design program or word processor. Your booklet needs pages in multiples of four because each sheet folds in half to create four printed surfaces. Add blank pages at the end if your content doesn’t naturally fit this requirement. Choose your paper weight based on how readers will use your booklet: 100 lb text weight works well for standard catalogues and programs, while 80 lb text keeps costs lower for high-volume mailings. Select heavier cover stock (typically 100 lb cover or 12 pt card stock) to protect inner pages and create a more substantial feel.

"Proper page planning prevents production delays and keeps your project within budget."

Find a Canadian printer and request quotes

Contact at least three Canadian printers to compare pricing and turnaround times. Request quotes that include your exact specifications: page count, paper weights, colour printing requirements, and desired quantity. Ask whether they charge setup fees or offer bulk pricing discounts at higher quantities. Most printers provide quotes within 24 hours and many offer free design reviews to catch potential issues before production starts. Confirm that production happens in Canada if you want to avoid international shipping delays and customs complications.

Review proofs and approve your order

Request a digital proof before your printer starts production. Check that all page numbers appear correctly, images print clearly, and colours match your brand standards. Verify that text near the spine stays within safe zones, as saddle stitch booklets require a quarter-inch margin from the fold to prevent content from disappearing into the binding. Pay special attention to pages in the centre of your booklet, where page creep can shift content slightly toward the spine. Approve your proof in writing once you confirm everything looks correct, then expect your completed saddle stitch booklets to ship within five to seven business days for standard orders.

Key specs and options to know

Understanding your specification options helps you make informed decisions that affect both cost and final quality. Canadian printers offer saddle stitch booklets in various configurations, and knowing which choices matter for your project keeps you from overpaying for features you don’t need or underestimating what your booklet requires. Each specification you select impacts production time, durability, and how readers interact with your finished product.

Page count limitations

Your saddle stitch booklets work best between 8 and 80 pages total. Projects under 8 pages usually make more sense as folded brochures, while anything over 80 pages becomes too thick for staples to penetrate reliably. You’ll notice bulging or page creep once you exceed 60 pages with heavier paper stocks, where inner pages stick out slightly beyond outer pages at the open edge. This happens because folded paper takes up space inside the spine, pushing centre pages further from the fold. Ask your printer about creep compensation if you’re planning a booklet near the upper page limit, as they can trim pages slightly to maintain clean edges.

Paper stock and coating options

Choose text weight paper (60 lb to 100 lb) for your interior pages and cover stock (80 lb to 130 lb cover weight) for the outer pages. Lighter text weights reduce bulk and cost for high-page-count projects, while heavier stocks create a more substantial feel that works well for presentation materials. Select matte coating when readers need to write notes or when you want to minimize glare under bright lights. Glossy coating makes colours appear more vibrant and protects against fingerprints, which matters for catalogues that get handled frequently.

"Paper weight affects both the durability of your booklet and how many pages you can bind successfully."

Size and format choices

Standard sizes include 8.5 x 11 inches (letter size), 5.5 x 8.5 inches (half letter), and 8.5 x 5.5 inches (landscape half letter). Letter-sized booklets cost less to produce because printers can fit more copies on standard press sheets, reducing paper waste. Smaller formats like 6 x 9 inches work better for pocket guides or event programs that people carry with them. Custom sizes increase your printing costs by 10 to 30 percent because they require special cutting and potentially waste more paper during production.

Colour and finishing details

You can print saddle stitch booklets in full colour, black and white, or combinations where covers get colour treatment and interiors stay black and white to control costs. Full-colour printing adds $0.50 to $2.00 per unit depending on page count and quantity. Request bleed on pages with background colours or images that extend to the edge, which requires your design elements to extend one-eighth inch beyond trim lines. Standard finishing options include UV coating for extra protection on covers or spot UV to highlight specific design elements like logos.

Saddle stitch vs other booklet binding methods

Choosing the right binding method affects how your booklet functions, how long it lasts, and what you pay per unit. Saddle stitch booklets work well for short-run projects with moderate page counts, but other binding methods offer advantages for specific use cases. Your decision depends on factors like page count, budget, how readers will use the booklet, and the professional image you want to project. Understanding what each binding method does best helps you match the right solution to your project requirements.

Perfect binding for thicker publications

Perfect binding glues pages together at the spine and wraps them in a separate cover, creating a flat spine where you can print titles and author names. This method handles page counts from 40 pages to 400 pages, making it the right choice when saddle stitching won’t work. Your booklets look more like traditional books with perfect binding, which adds perceived value for annual reports, product catalogues, and training manuals. The trade-off comes in cost, as perfect binding typically runs 40 to 60 percent more expensive than saddle stitching for comparable projects under 100 pages.

"Perfect binding creates a bookshelf-ready appearance but requires higher page counts to work reliably."

Coil and Wire-O binding for durability

Coil binding threads a plastic spiral through holes punched along the edge of your pages, while Wire-O uses a double-loop wire. Both methods let your booklet lay completely flat when opened and allow pages to fold back 360 degrees without damage. These bindings excel for cookbooks, instruction manuals, and workbooks where readers need hands-free reference. You pay 20 to 40 percent more than saddle stitch binding, and production takes longer because each booklet requires individual binding. Wire-O creates a more professional look than plastic coils, but both add bulk that makes booklets harder to mail in standard envelopes.

Saddle stitch booklet pricing guide

Your saddle stitch booklet costs depend on quantity, page count, paper quality, and colour printing choices. Canadian printers typically charge between $1.50 and $8.00 per booklet for standard specifications, with unit prices dropping significantly as you order more copies. Understanding how each variable affects pricing helps you make smart decisions that balance quality with budget constraints. Request quotes from multiple printers because pricing structures vary, and what costs less at one shop might cost more at another depending on their equipment and volume capabilities.

Base pricing by quantity

You’ll notice the biggest price drops happen at specific quantity breaks: 25, 50, 100, 250, 500, 1,000, and 2,500 units. A 24-page booklet with full-colour covers and black-and-white interiors typically costs $6.50 per unit at 25 copies, $4.25 at 100 copies, and $2.10 at 500 copies. Ordering 1,000 units drops your per-unit cost to around $1.60. These prices assume 8.5 x 11-inch size, 100 lb text weight interiors, and 100 lb cover stock. Smaller formats like 5.5 x 8.5 inches cost roughly 15 to 20 percent less because printers fit more booklets per press sheet, reducing paper waste and production time.

Additional cost factors

Adding full-colour printing to interior pages increases costs by $0.75 to $2.50 per booklet depending on page count. Higher page counts require more paper and folding time, with costs rising approximately $0.15 to $0.30 per additional four pages. Premium paper stocks like 130 lb cover or specialty textures add 10 to 25 percent to your base price. Rush production cuts your timeline from seven days to two or three business days but typically costs 30 to 50 percent more than standard turnaround. Coating options like UV coating or aqueous coating on covers add $0.20 to $0.50 per unit.

"Order quantities near the next price break threshold to maximize your budget efficiency."

How to reduce printing costs

Keep your interior pages black and white while using full colour only on covers to reduce expenses without sacrificing visual impact. Standard sizes cost less than custom dimensions, so choose 8.5 x 11 inches or 5.5 x 8.5 inches whenever your design allows. Reduce your page count by tightening content and layouts, as dropping from 28 pages to 24 pages can save $0.40 to $0.80 per booklet. Order slightly more copies to reach the next quantity break if you’ll eventually need additional booklets, since reprinting small quantities later costs more per unit than ordering extras upfront. Skip coating and specialty finishes on internal projects like training materials or employee handbooks where durability matters more than premium appearance.

Final thoughts

Saddle stitch booklets give you an affordable, professional printing solution for projects between 8 and 80 pages. Your choice of paper stock, page count, and quantity directly affects both cost and quality, so plan these specifications carefully before requesting quotes. Understanding the differences between binding methods helps you select the right option for your specific needs, whether you’re printing event programs, product catalogues, or marketing materials.

Canadian businesses benefit from working with local printers who understand regional preferences and offer faster turnaround times. You avoid international shipping delays and customs complications while supporting domestic production. Get a free quote on your custom saddle stitch booklets from a Canadian printer that delivers quality results within 5-7 business days. Your project deserves professional printing that meets your timeline and budget requirements.